The Standard

As there is no Thai standard for the application and maintenance of storage systems, ROS Thailand are therefore referring to the European “Steel static storage systems – Application and maintenance of storage equipment EN15635” standard when it comes to categorise the level of damage(s) on an upright frame, and the action that needs to be taken

When inspecting the pallet racking upright frame, the following guidelines are followed.

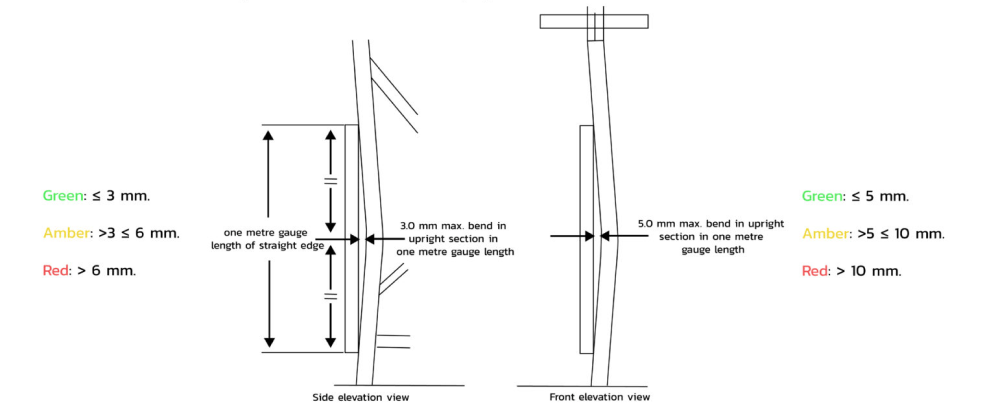

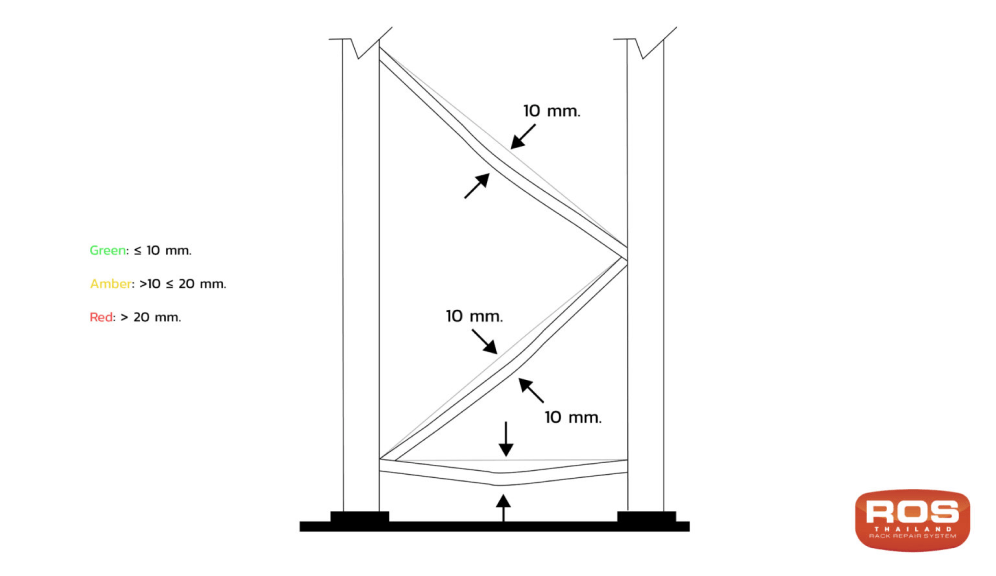

The damages are categorised into three groups, each represented by a colour:

● Green: The damage/bending is within the safe limit, but shall be recorded and reviewed at set intervals to make sure it does not get worse.

● Amber: The damage/bending is more than what is accepted as being categorised as Green, but less than twice the number. The area shall be set to be repaired within maximum 4 weeks from the damage being noticed.

● Red: The damage/bending is more than twice what is accepted as Green and shall be off-loaded immediately and repaired as soon as possible.

The bend is measured using a 1 m long straight square rod. the gap (if any) between the rod and the upright is measured at its maximum dent.

Please note that if there are two Green damages on the same frame, they will be considered as Amber.

If two Amber damages on the same frame they will be considered as Red.

Action to be taken with each Colour Code